Before working with excavators, you need to know how they work. Excavators are essential heavy construction machines designed for digging, moving and lifting materials. They help make construction and excavation projects safer and more efficient. Understanding what the basic parts of an excavator are can help you be a better operator. Learn the excavator’s components and functions in this guide.

10 Main Parts of an Excavator

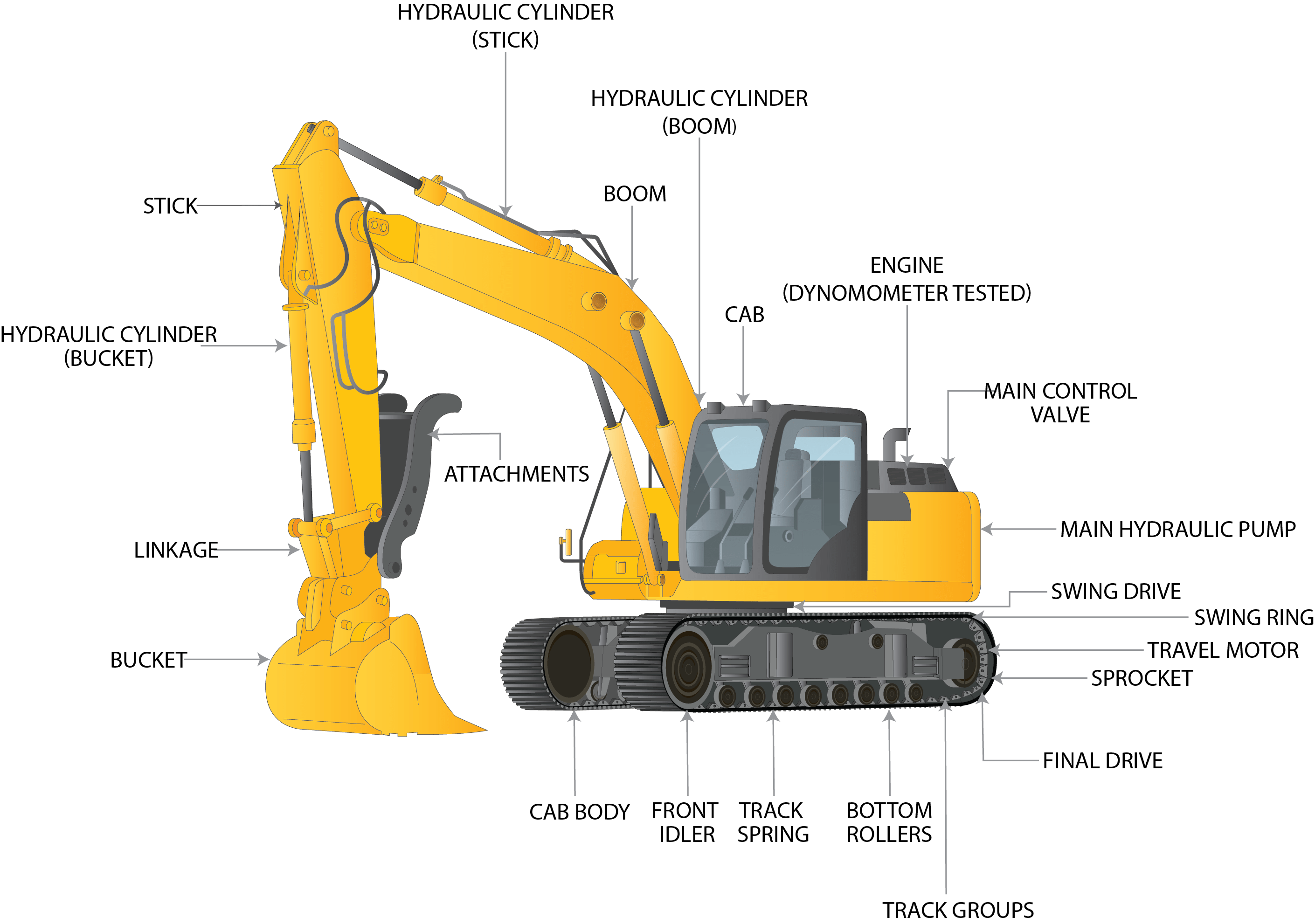

Knowing the basic parts of an excavator and how they work can help you choose, work with and maintain your machine. You’ll know what each part is, what it does and how everything fits together. Here are the main excavator components:

1. Boom

The boom is a fundamental component of an excavator. This large main part extends outward from the machine’s body. It primarily provides the excavator with its reach, allowing the operator to position the arm and bucket precisely for digging, lifting or placing materials. Booms come in various lengths and configurations, depending on the excavator’s intended application. Long booms are generally used for tasks requiring an extended reach, while shorter booms are better for confined spaces.

2. Arm

The arm, also called the stick, connects the boom to the bucket and helps control the excavation’s depth and precision. By extending and retracting the arm, the operator can adjust the distance between the boom and bucket, enabling precise digging, grading and lifting. The arm’s length varies depending on the excavator’s size. While mini excavators have shorter arms for better maneuverability in tight spaces, larger excavators have longer sticks, allowing for deep excavations.

3. Bucket

The bucket is the attachment at the end of the arm responsible for digging, scooping and carrying materials. Buckets come in various shapes and sizes, each designed for specific tasks. Excavator buckets typically have teeth or cutting edges for breaking through tough soil or rock. They can be swapped out for other attachments, like grapples or thumbs, to expand the excavator’s capabilities. The bucket’s size and shape significantly affect productivity and efficiency, so choosing the right one for the application is important.

4. Cab

The cab is the operator’s compartment. It contains the operator’s seat and the control panel. From here, the operator manages the machine’s functions, using various controls, joysticks and pedals to operate the boom, arm, bucket and other movements like rotation and travel. Modern excavator cabs are equipped with air conditioning, ergonomic seating and advanced technology, enhancing operator safety, comfort and productivity.

5. Undercarriage

The excavator’s undercarriage supports the machine’s weight, provides stability and facilitates movement. It includes tracks or wheels, depending on the excavator type. Tracks offer excellent traction and weight distribution, enabling crawler excavators to navigate rough and uneven terrains more easily. Wheeled excavators provide maximum agility on smoother surfaces such as asphalt and allow more mobility. The undercarriage may have features like adjustable width or retractable tracks to adapt to various job site conditions, ensuring the excavator’s stability and maneuverability.